Do you suspect a gas leak in your home or outside? Gas leaks are a serious threat. It is critical that you call professional technicians to come test your gas system. GIS will provide better solution to maintain gas pipelines and fixtures. GIS tools and technology will allow to quickly determine whether there are really any leaks on your residential site. Once we've discovered evidence of a leaking gas problem, the next step is to locate the exact positioning of the leak. It could be underground or in other places that you could not otherwise detect without expert gas technicians. Even if it's deep within a concrete slab. GIS will save you time, effort, hassle and worry. After you contact technician, there are some things you need to do until they arrive:

· Turn off the gas tap

· Open all the doors and windows

· Don’t turn the lights on and off since that can produce sparks and might cause the explosion

· Do not light a cigar or a candle in the apartment

Gas Utility Data Collection Using Ground Penetrating Radar (GPR) Scanning

GPR method can be used in a range of fields such as environmental, archaeological, transportation projects and many others. It is used during the entire span of the project, from the design phase to investigate the ground all the way to maintenance and operation to verify concrete thickness and/or to locate reinforcing bars and buried utility conduits.

.jpg)

Outdoor Ground Penetrating Radar (GPR) – locating metallic and non-metallic pipes, cables and other structures from 2-3m subsurface; suited to roads, construction sites, footpaths, car parks, industrial sites, and other outdoor sites.

Indoor GPR – for locating 300-400mm subsurface; suited to building sites and concrete scanning to locating post-tension cables and rebar (before concrete cutting or core hole drilling performed by on-site tradesmen). This GPR scanning can also be used to locate a reinforcement bar (reo bar) concealed in walls. GPR scanning includes reports and clear and accurate 3D imaging of subsurface infrastructure.

GAS Asset Audit, Monitoring and Leak Solutions Apps

Gas leaks can cause major incidents resulting in both human injuries and financial losses. To avoid such circumstances, a considerable amount of effort has been devoted to the development of reliable techniques for detecting gas leakage. As knowing about the existence of a leak is not always enough to launch a corrective action, some of the leak detection techniques were designed to allow the possibility of locating the leak. The main purpose of this article is to identify the state-of-the-art in leak detection and localization methods and monitoring. Additionally, we evaluate the capabilities of these techniques in order to identify the advantages and disadvantages of using each leak detection solution.

.jpg)

You can use this app to support regulatory compliance, customer satisfaction, and improving planning/operations efficiency. GIS related software for Gas utilities provides ready-to-deploy mapping applications and analysis models for use in network planning, maintenance, compliance, and marketing. Executives, office and field staff, customers, and the public benefit from these map-based insights. The ArcGIS for Gas utilities solutions can be used out-of-the-box and easily configured to meet organization-specific requirements. The included templates enable you to quickly deliver essential workflows without having to build them from scratch, and with the assurance of following best practices. GIS for Gas Utilities includes a suite of apps for common tasks. For example, the ArcGIS Leak Survey apps help you schedule, monitor, and track leak surveys to stay in compliance. Use the maintain Assets maps and apps for improved maintenance of your gas network records, to save time and money, and improve public safety.

The Leak Survey Manager allows operation managers to view the progress of leak surveys and assign new work using a configuration of the Web AppBuilder for ArcGIS. This app provides managers with reporting layers that summarize leak surveys by area, leak survey types by due date, and a set of tools to create and assign leak survey assignments. Gas utilities are required to periodically survey gas service lines for leaks by “walking” the service line. Utilities may be required to survey 33% of all residential gas services and 100% of all business district and public building gas services for leaks by a utility employee or contractor on foot. This solution also includes Python scripts using the Automated Setup & Reporting tools to calculate the following:

· Asset count (footage of mains and number of services) for leak survey grids

· Asset count for town overview area

· Leak survey report for town overviews area

· Increased productivity of service line surveyors.

· Time savings for inspectors and supervisors.

· Reduced errors and enhanced data quality.

· Surveyors can easily select and manage services right on their smartphone.

· Enhanced GIS data quality on services using GPS tagging.

The Leak Survey Collector map can be used by field technicians to record leak surveys in the field. Using ArcGIS for Server, follow the steps below to publish the service required for Leak Survey Collector. To publish the Leak Survey Collector map and register it to your ArcGIS organization, complete the following steps:

· Publish the map as a feature service using ArcGIS for Server or

· ArcGIS Enterprise with Create, Query, Delete, Sync, and Update capabilities.

This app lets the user create a compressed air leak survey report. Once leaks are identified and information is entered, the data can be used to generate a comprehensive excel report that include estimated CFM loss, up-to-date cost avoidance, leak location photos (taken with your smartphone or tablet), and greenhouse gas reductions. Survey quality assurance is optimized by identifying leaks that have been repaired and leaks that have not been repaired.

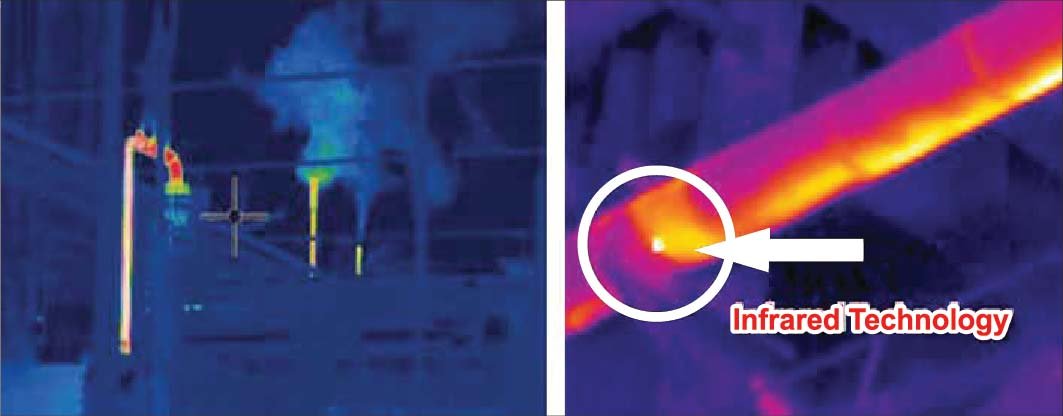

Thermal Cameras Detect Gas Leaks

Thermal cameras detect gas leaks that are hazardous for human health and the environment by visualizing them. The principle behind this method of gas detection is simple: some gases behave as selective radiators with low throughput and reflectivity – and high emissivity. This means that a highly sensitive thermal camera calibrated to the correct spectral range can easily observe a wide range of gases. As a result, special LWIR and MWIR thermal cameras have been developed to detect gas leaks, including, for example, the problematic SF6, which is 24,000x more hazardous for the environment than the greenhouse gas CO2. So long as the gas is a selective radiator in the spectral range of the thermal camera and its filter, it will be detected.

The key conditions for gas visibility on a thermal camera readout are as follows:

· The gas must absorb infra-red radiation in a wavelength that is visible to the thermal camera and optical filter

· The gas cloud must have a high bright contrast compared with the background

· The instantaneous gas temperature must be different than the background

· The gas cloud’s movement helps its visibility

Those interested in a detailed physical explanation of the principles are referred to our website. http://www.overallvision.com.au/vision.com.au/

Climate Change

Gas emissions contribute to the growth of global warming. Industrial firms pay billions of dollars for emissions in regulation penalties and damage, and the leaks represent a fatal risk for both employees and residents. Thermal camera inspections can detect the leaks of dozens of volatile organic compounds, including the greenhouse gas sulphur hexafluoride. Detecting gases with a thermal camera enables leaks to be caught for tens of volatile organic compounds, including greenhouse gas sulphur hexafluoride, SF6.

A specialized thermal camera for gas detection is a fast, contact-less measurement tool which can be used in difficult-to-access places. It can detect small leaks from several meters away, as well as larger leaks at hundreds of meters of distance. It can also detect leaks on moving vehicles, which significantly increases the safety of both the inspector and the inspected item. To ensure success, inspectors must select a suitable spectral range (MWIR or LWIR) and utilize a band pass filter depending on which gases are to be detected.

Dr. Sultana Nasrin, Snb.sdml@gmail.com, https://www.geospatialaus.com/about/, http://www.overallvision.com.au/vision.com.au/