Barapukuria Coal Mine Company Ltd (BCMCL) has signed a contract on 16 February 2017 for a feasibility study for the expansion of the existing underground mining operation with US-based John T Boyd Company and Mazumder Enterprise of Bangladesh where witnessed by over 100 peoples at Westin Hotel in Dhaka. Guests attending the contract signing ceremony in presence of Mustafizur Rahman Fizar M.P., the Honorable Minister for Ministry of Primary and Mass Education, Nazimuddin Chowdhury, Secretary Energy and Mineral Resources Division, Abul Mansur Md Faizullah, Chairman Petrobangla, Director's of Petrobangla, MD of Barapukuria Coal Mine, MD of Maddhapara Granite Mine, President and CEO of John T. Boyd, Managing Director of John T. Boyd, Gao Fazhong, Regional Manager, BGP Inc. China National Petroleum Corporation, national and local medias, high officials of Energy and Mineral Resources Division, Petrobangla and Barapukuria. As per contract between BCMCL and John T Boyd, the feasibility study of the project will be completed within the 18 months period with a project cost of Tk 68.31 crore.

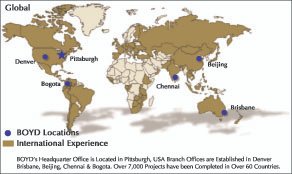

John T. Boyd Company of USA, mining and geological consultants, founded in 1943, is one of the largest, privately owned, mining consulting firms exclusively serving the domestic and international coal, mineral, and natural gas industries. The BOYD name is highly respected as an international mining consultant for its mining acumen, quality reporting, and ethical conduct. BOYD is a recognized leader in coal, as well as industrial minerals.

The objective of the study is to provide consulting services for feasibility study and mine design for extension of existing underground mining operation of Barapukuria Coal Mine towards the southern and the northern side of the Basin without interruption of the present production located at Chowhati, Parbatipur in Dinajpur. The study is to be carried out in 1.5 sq.km in the northern part and 3 sq.km in the southern part of the basin and for improving the annual production of Barapukuria Mine from 1.0 million ton to 1.5 million ton.

The main objectives of the feasibility study are as follows:

· To know the actual reserves and suitable mining method and yearly production in the southern part of the basin and far south part of the lease area and the northern side of the present mining area of the basin.

· To find out the economical viability of these proposed expansion mining area.

· To know the actual hydrological condition, how many slice can be mined, amount of coal can be mined, life of mine, etc.

The study shall include the followings;

· 3-D seismic survey (area ±4.5 sq.km, target depth upto 450m.

· Exploratory drilling (15nos. of bore hole) including geophysical and geological logging.

· Pumping test and hydro-geological study.

· Computer generated 3-D Geological model of the resources.

· The determination of geological and hydro-geological conditions, mining method, actual resources and reserve, yearly production rate, mine life etc.

· Mine design.

· EIA, EMP and Socio-economic Impacts Assessment.

· Assessment of resettlement requirements and preparation of a resettlement action plan.

· Detailed economic analysis and to determine if the project is economically viable or not;

· Necessary lab test etc.

BGP Inc. China National Petroleum Corporation will be engaged for carrying out 3D seismic survey and Mining Associates Pvt. Ltd. of India will be worked as drilling sub-contractor of John T. Boyd for this project.

The five coal fields have been discovered so far in the northern areas of the country. Subsequent exploration proved the existence of Gondwana coal at Jamalganj (1962), Barapukuria (1985), Khalashpir (1989), Dighipara (1995) and Phulbari (1997).

The coal fields discovered so far have not been developed except Barapukuria. Barapukuria underground coal mine, the first ever coal mine in the country is being suffering from many problems especially geological, hydro-geological, experiencing high temperature and subsidence. The underground method of mining has proved to be less productive than expected and efforts are being taken for remedial measures to increase production from Barapukuria. The commercial extraction of coal has been started from Barapukuria Coal Fields using underground mining method since 2005.

In 1985, Geological Survey of Bangladesh (GSB) discovered high quality bituminous coal spread over an area of 6.68 sq.km at a depth ranging from 118 to 509 meters at Barapukuria under Parbatipur upazilla in the district of Dinajpur. During 1987-1991 a UK based company M/S Wardell Armstrong carried out the Techno-Economic Feasibility study on this coal under ODA financial support. Based upon the Wardell Armstrong report, Petrobangla undertook Barapukuria Coal Mine Development Project. A total of 33 nos of boreholes were drilled, delimited the area of reserve, determined the structure and the coal seam characteristics were identified in terms of thickness, quality etc. at that time. There are six coal layers or seams named as I, II III.IV.V and VI from top to bottom. Among these, the seam VI is the most well developed, consistent, and the thickest one. Of the total coal reserve of 390 million ton in Barapukuria field, the seam VI contains 336 million tons, i.e. 86% of the total reserve.

In 1994, an underground mine construction contract under a supplier’s credit of US$194.91 Million was signed between China National Machinery Import & Export Corporation (CMC) and Petrobangla with a production view to develop an underground mine having a production capacity of 1.0 million ton of coal per annum. To ensure proper implementation of the project and smooth functioning of the mine operation, Barapukuria Coal Mining Company Limited was formed and registered as a company on August 04, 1998 under the companies Act 1994.

According to the necessity during development and production period of the mine, additional 5 boreholes were drilled by XMC/CMC consortium in the mining area during 2013-2014. Asia Energy Corporation drilled 4 nos of boreholes in 2005 at the southern side of Barapukuria Lease Area and confirmed the extension of the coal seam towards south. Institute of Water Modeling (IWM), Bangladesh drilled 8 nos of exploratory boreholes in 2013-2014 at the northern side of the coal field under a study work relating to groundwater modeling in that area.

The surface geology over the entire coal field area was covered by Barind Clay (Madhupur Clay). Ground water bearing strata (Dupi-Tila) is uncomfortably overlays the Gondwana (Permian) coal bearing sediments. These are folded into an asymmetric syncline or basin, whose axis strikes approximately North-South. A major fault forms the eastern limit of the deposit, beyond which, Archaean Basement rock (Pre-Cambrian) are present immediately below the Dupi-Tila. The Gondwana sequence comprises predominantly sandstone, with subordinate siltstones and mudstones, which contains up to six coal seams in the center of the Basin. The lowest of these, seam VI is the principle target seam of Barapukuria and has an average thickness of 36m. An in-situ geological reserve of about 390 million metric ton of coal was calculated for the entire basin. Recovery is constrained by mine layout, method of extraction, number of slices to be mined, all of which are dependent on going experience during the production phases.

Barapukuria mine is developed by multi-slice long wall mining with caving. The first slice of 3 m height has already been extracted and the second slice of 6 m height is under progress by Long Wall Top Coal Caving method. But due to severe water problem again returned back to long wall mining method during end of 2016. In the northern part of Barapukuria Coal Mine, there is potentiality of open cast mining of seam VI, covering an area of 2.71 sq. km. having a deposit of 118 million tons of coal, at a depth of 100-120m. A techno-economic feasibility study is required for open cast mining in the northern zone.

After completion first phase coal production under M&P contract, a consortium of Xuzhou Coal Mining Group Corporation (XMC) and China National Machinery Import & Export Corporation engaged by BCMCL as "Management, Production, Maintenance and Provisioning Services" (MPM&P) contractor by invitation of international tender. With a contract period for 72 months, final contract signed on 10 December 2012 which was activated from 11 August 2011.

The commercial production from 1st slice of central part of the mine started from 10 Sep, 2005 and successfully completed on 14 Feb, 2012. Within this period production was fully completed from 11 (eleven) longwall faces and partially completed from 1 (one) longwall face (1110 face) and total 28.2 km roadways was completed. A total of 4.2 million ton coal has been produced from the 1st slice of the mine. The roadway development activities of 1204 face resumed on 10 Sep, 2011 intention to produce coal from second slice of sixth seam from central part of Barapukuria Coal Basin after successful completion of production from the 1st slice. Coal production activities resumed on 15 March 2012 from above mentioned face after completion of development works. Longwall Top Coal Caving (LTCC) method has been adopted from 8th May, 2013 in place of longwall Mining Method. LTCC is known as a Mass Production Method of producing coal in Underground with less production cost and less time. There is a plan of increasing the caving height in keeping consideration of mine safety to get much more coal production. With this LTCC method daily production has reached average 4,000 ton to 4,500 ton and most of the coal is being delivering to the power plant for power generation.

The Barapukuria coal deposit has a proved area of approx. 5.25 sq.km. The coal reserve of Barapukuria is estimated at 390 million ton . This is based on the demonstrated reserve of 303 million ton contained in more consistent and important seams II, IV and VI plus the inferred reserve of about 87 million ton contained in irregular and inconsistent seams I, III and V.

Barapukuria coal has Moisture content 10.0%, Ash 12.4%, Sulfur 0.53%, Fixed Carbon 48.4%, Volatile Matter 29.2% with a calorific value of 11040 btu/lb. Necessary steps need to be addressed for feasibility study concerning open-pit mining at northern part of Barapukuria Coal Basin without hampering the present mining activities of the mine.

Coal in Bangladesh do not occur at surface but mostly lie at relatively deeper level except Phulbari and Barapukuria while in neighboring West Bengal and Bihar, the coal occur at surface as well as in shallower depth and for this reason major part of coal mining in northeast India are operated by open pit method, a much easier and less costly mining method with higher coal recovery compared to underground mining.

The government's development goals for the energy sector are to provide energy for sustainable economic growth and for maintaining energy security. The exploration and exploitation of coal need to be expedited through foreign and private investment. At the same time, it is necessary to formulate strategy for attracting investment for developing all the coal fields of Bangladesh.

Mortuza Ahmad Faruque;

Energy Specialist & Former Managing Director of BAPEX