Gladstone, the fourth largest coal port of the world and the largest multi-commodity port of Australian state of Queensland, could be an ideal model for the development of Matarbari and Maheshkhali islands of Bangladesh as a fuel import port and energy hub.

From exclusive own fuel-based energy development, Bangladesh is venturing for almost exclusively imported fuel-dependent economy in not too a distant future. It has embarked on the plan for importing LNG and coal for fuelling its burgeoning economic growth. The major challenges, apart from huge investment, are the need for developing human resource and absorbing expected price shock and developing import facilities. Bangladesh does not have deep sea port. The existing Chittagong and Mongla seaports and under construction Payra port do not have required draft for providing access to standard coal ships and LNG vessels. The only suitable option is Matarbari and Maheshkhali islands of Cox’s Bazar. Australia has a major multi-commodity port at Gladstone, about 550 Km north of Queensland and 100 Km south east of Rockhampton. It has two large coal export terminals (RG Tanna, Barney Point and Wiggins Island Coal Export), three LNG Processing Plants and Export Terminals, one 1,680 MW coal-fired power plants and several industries. In many ways Gladstone can be an ideal city for Bangladesh to take into consideration as the government is now executing plan for developing these Matarbari and Maheshkhali islands as the major energy & power hub of Bangladesh.

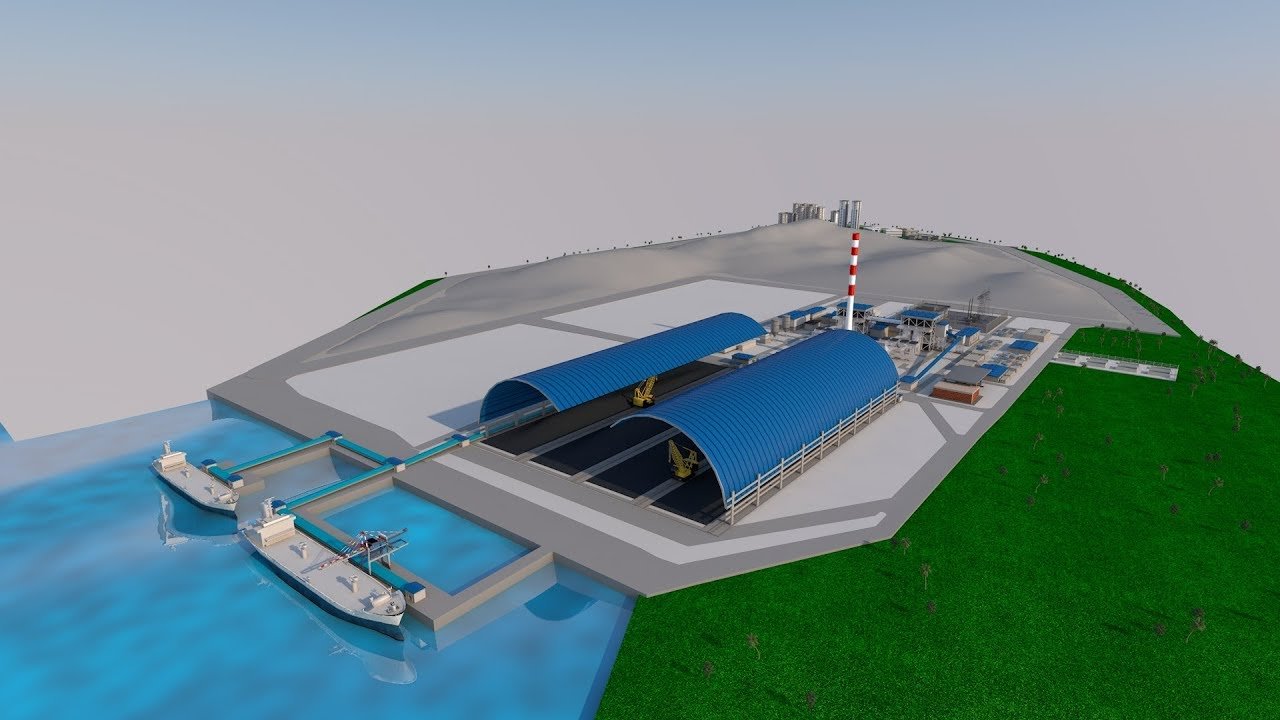

Implementation of a JICA-assisted coal port at Matarbari is advancing. There is a plan to expand this to a coal transshipment terminal in future. The present coal port would cater coal import to an under implementation 1,320 MW coal-fired power plant by CPGCBL at Matabari. The government is also going ahead with programs for setting up of 8-10 similar capacity coal-based power plants at Matarbari and Maheshkhali islands. The coal for all these plants would be supplied from the future coal transfer terminal planned to be set up at Matarbari.

For the construction of coal and LNG import terminals, it is essential that these are located besides waterways of at least 16-meter plus draft for loaded coal carrying vessels and LNG carriers to anchor. The riverine delta of Bangladesh has costal lines having mostly 6-8 meters draft, excepting south Matarbari. This makes it ideal for coal port and land-based LNG terminal. That is why, after JICA feasibility study, Matarbari has been selected for the coal port with ultimate plan for converting it to coal transfer terminal. Some floating LNG terminals are being set up in Matarbari and few land-based LNG terminals are planned for Kutubdia island and Matarbari. There has been no confirmation yet for the huge investment required for the coal transfer terminal as these days the trend is growing for discouraging coal more and more and going into other options. Bangladesh may find it very challenging in finding the interested investors in coal terminal construction.

Gladstone Facilities

Situated between Caliope and Boyne rivers and not far from the confluence of the Pacific Ocean, Gladstone is the largest multi-commodity shipping port of Queensland. Port of Gladstone is the fourth largest coal port of the world. It exports about 50 million tonnes of coal annually. The main import commodities are Bauxite and petroleum products.

Coal Port Terminals at Gladstone

Gladstone has three coal export terminals. Two of these RG Tanna and Barney Point are Under Gladstone Port Corporation (GPC) and WICET Terminal is privately owned by a consortium of Aquilia Resources, Glencore, New Hope Group, Westfarmers Currah and Yancoal.

RG Tanna Terminal

The terminal has a capacity to handle 72 million tonnes of coal export per year. It has no responsibility with selling and purchasing of coal. It receives coal from 17 coal mines of Central Queensland. Some of these mines are located at 350 -400 Km from the terminal. The terminal handles 40 varieties of coal. The port channel has draft suitable for 220,00+DWT vessels. The extensive dust and water management technology makes it a very ideal environment-friendly coal port. The terminal follows As/NZs 1400-2004 environmental standard and AS/ NZs ISO 9001-2008 Quality Assurance Certificate.

Three trains can be unloaded simultaneously at 6,000 tonnes per hour, applying automatic wagon door opening. Coal is transported to overhead conveyor system. The terminal has 22 stockpiles with a total capacity of 5.6 million tonnes. Three ship loaders load coal to the ship. Four ships can berth at the terminal but three ships can be loaded simultaneously. Coal from overhead conveyor is directed to stockpile. Bulldozers form and maintain the stockpiles. Coal is reclaimed using bulldozers pushing coal into the stockpile. Stockpiles contain three stockpile dischargers. Three vessels are loaded simultaneously at 6,000 tonnes per hour.

Extreme care is taken for quality control at every stage. No water run-off is possible leaving the terminal area without treatment and retention. Coal blending is done during ship loading. Control gates on stockpile dischargers allow feed rates to be controlled to meet required blending rates. The terminal can blend up to five different varieties of coal.

Monash University and RMIT University of Australia with the assistance of Department of Foreign Affairs and Trade (DFAT) implemented an extensive capacity development program for senior and mid-level officials of Bangladesh Energy & Power sector officials in Australia in several groups. They participated in seminars, workshops and industry visits. One of their activities was visiting port facilities and installations in Gladstone. A delegation of Parliamentary Standing Committee on Power and Energy also visited Gladstone. These visits have definitely given the Bangladeshi policymakers and energy project managers first hand ideas about how nature and environment can be preserved mostly unaffected in development and operation of energy projects and infrastructures.

Barney Point Terminal

Single train unloading point 2,000 metric tonnes per annum capacity of coal from far away mines of central Queensland. The trains have automatic wagon door opening and bottom dump discharge facility to underground feeder system. Coal is transported to stockpile via coal stacker. Remaining facilities are same as RG Tanna.

Wiggins Island Coal Export Terminal Pty Ltd (WICET): WICET is a private owned company of Aquilia Resources, Glencore, New Hope Group, WestfarmersCurragh an Yancoal. This modern coal export terminal has capacity for handling 27 million tonnes per annum with plan for expanding to 120 million tonnes in due course. The coal is transported by rain to coal intake terminal about 6 KM from the terminal. The same principal of automatic door opening and bottom dump wagon discharge procedure is applied for dumping coal to underground conveyor system. Coal goes to stockpile and later transported to ship anchored into berth deep into water by coal stacker and conveyor system.

The above terminals are ideally located for exporting coal to Bangladesh. Queensland government appears very keen to discuss coal export opportunities to Bangladesh. Bangladesh should take these opportunities for discussing coal import from Queensland using coal terminals at Gladstone.

NRG Power Plant

Apart from the coal export terminals the small town of Gladstone also has a 1,680 MW capacity coal-based power plant using sub critical technology. The power plant is owned by a consortium of Rio Tinto (42.125%), NRG Energy (37.50%), SLMA GPS pty Ltd (6.50%), RYOWA GPS Pty Ltd (7.26%) and YKK (4.715). Six steam turbines each of 275 MW capacity use 27 million tonnes of black coal per year transported to the plant from Curragh Coal Mine 200 KM away by rail. The plant use sea water for cooling. Very stringent emission and water management standard keeps the plant almost zero carbon footprint for over 50 years. The water used in the plant goes through series of pre-treatment and retention prior to discharge in the stream. The 125-meter high chimney let out almost clean smoke to the atmosphere. The excellent ash management system of the plant can be replicated in Bangladesh. Most of the fly ash generated in the process is consumed by the cement factories in the area. Bottom ash in very careful manner is used in land reclamation. Bangladeshi officials during their visit have eye-witnessed the plant operation, emission control, ash management and water management system. Bangladesh may discuss with NRG Power Plant management for training of its operators and Engineers in the plant. Although it is a sub critical power plant but the principal of emissions control, HSE and ash management is the same.

Matarbari Coal Port/ Coal Transfer Terminal

Bangladesh Government with the assistance of JICA is now constructing a coal port at Matarbari for the under construction 2X660 MW imported coal-fired power plant. There is a plan to double the capacity of power generation in due course. The government has a program of making the port into a coal transfer terminal of 40 million tonnes annual capacity for feeding all the planned power plants in Maheshkhali and Matarbari area. Right now, the plan is to develop CTT through Public Private Partnership (PPP). Unlike the terminals at Gladstone, Matarbari will have import terminals, but in many ways the operation of the port and terminal could replicate the technology, HSE standards applied at Gladstone terminals. About 100 Bangladeshi officials of Power and Energy Sector have eye-witnessed operation of coal terminals while visiting Australia under Australian Fellowship Award Program.

LNG Processing Plants at Curtis Island

Three large LNG processing plants in Curtis Island in the vicinity of Gladstone produce LNG from Coal Seam Gas extracted from thousands of wells drilled in coal mines in Surat and Bowen Basin. The gas after treatment in some central processing plants is transported through three different gas transmission pipelines 350-400 Km long to Curtis Island. The three plants are located side by side. The process involves removal of CO2 and water prior to feeding in the refrigeration system. All the three use ConocoPhilips-patented optimized cascade system of refrigeration to produce super cool liquid methane (LNG). This is essentially three refrigerant circuit removing propane, ethylene and chilling methane. Convey these to purpose-built cryogenic LNG vessels which anchor at jetties located in the shore of each plant. LNG is a super cooled (-161 degree Celsius) liquid methane. The original volume is compressed to 1/600 for ease of transportation of large volume to longer distance.

Gladstone LNG (GLNG)

Jointly owned by Santos (30%), Petronas (27.5%) Total (27.5%) and KOGAS (5%) GLNG plant is located at Hamilton Point in West Curtis Island. It has a capacity of 4 million tonnes of LNG.

Asia Pacific LNG (APLNG)

Owned by a consortium of Origin Energy (37.5%), ConocoPhilips (37.5%) and SINOPEC (25%) APLNG has capacity of 9 million tonnes.

QCLNG/QGC

Shell is the owner and current operator of the plant. It has capacity of 8.5 million tonnes per annum and uses two trains. CNOOC has 50% share in train one and Tokyo Gas has 25% share in train two. QGC meets 10% of the gas demand of Australian east coast and 40% of Queensland. The rest of the LNG is exported.

LNG Import Facilities in Matarbari, Maheshkhali

Bangladesh government is implementing plan for importing LNG for meeting its existing and emerging gas deficit. Several FSRUs and some land-based terminals are at different stages of construction. The target is to import 3,500-4,000 MMCFD equivalent LNG by 2030. Bangladeshi Energy and Power sector officials have attended workshops conducted by senior officials of GNLG and QGC and also had cruise around Curtis Island LNG plants. Bangladesh will import LNG and import terminals will be operated by foreign companies. But Bangladesh officials have to monitor the operation and arrange evacuation of regasified LNG for gas grid. They will have to manage LNG purchase contracts. Curtis Island LNG plant owners can be a source of LNG import.

Gladstone, with coal ports, coal-fired power plant, LNG terminals and many other industries that operates using sophisticated technologies, offers Bangladesh a unique model to follow as far as practical for developing Matarbari, Maheshkhali as energy import and power generation hub of Bangladesh.

Saleque Sufi;

Contributing Editor, EP